The Louisiana state government, which collects about $1.3 billion a year in taxes from the oil and gas industry, is studying whether alternative fuels and other environmental measures can help reduce greenhouse gas or GHG emissions.

[Photo by the Louisiana DOTD.]

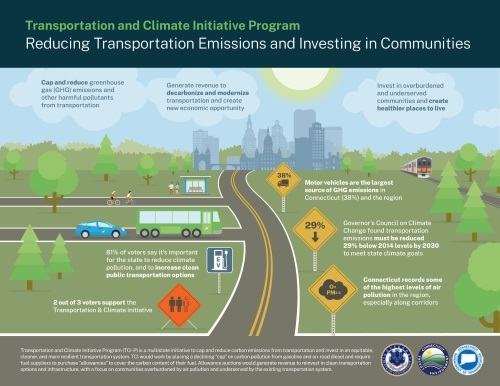

Gov. John Bel Edwards has created a 23-member Climate Initiatives Task Force charged with creating a plan to reduce greenhouse gas emissions to net-zero by 2050 – with the Louisiana Department of Transportation and Development poised to do the heavy lifting on transportation strategies within that plan to move towards the state’s GHG reduction goals.

“I think it’s a worthy effort to at least start a discussion about what needs to happen in Louisiana,” explained Louisiana DOTD Deputy Secretary Eric Kalivoda, co-chair of the task force’s transportation committee.

Devastating hurricanes, coastal subsidence, and rising sea levels – blamed on global warming – are eating away at Louisiana’s coastline. According to the governor’s office, if no significant action is taken, Louisiana could lose another 4,000 square miles of coast by 2050.

Kalivoda sees the transportation committee addressing four issues: demand management, conservation, alternative fuels, and “natural sequestration through reforestation.” The alternative fuel issue is the one that gets the most attention, and it usually focuses almost exclusively on electric vehicles, he said.

“A lot of people are going down the path of all-battery-powered electric, but I think a variety of fuel sources is the way to go,” including natural gas, hydrogen, biofuels, and traditional gasoline, he noted. “Gas and diesel engines are going to be part of the mix, certainly for the foreseeable future.”

Ann Vail, executive director of Louisiana Clean Fuels and a member of the task force, agreed.

“Oil and gas aren’t going to go away,” Vail said. “We’re looking at more of a buffet of fueling options. We have to look at biofuels, electric, and we already have a half-decent natural gas vehicle infrastructure here.”

Louisiana DOTD’s Kalivoda added that many of the 88,000 registered government vehicles in Louisiana could be converted to run on a variety of alternative fuels “as a demonstration project to the private sector. We can enter into contracts for fuel at facilities also open to the public and show the maintenance records and the problems we run into.”

Demand management simply means promoting telecommuting, compressed workweeks, remote learning, and virtual business meetings and conferences, actions that a majority of people now are familiar with, thanks to the pandemic. “The genie is out of the bottle, and I don’t think it’s going back in,” he noted.

Kalivoda said Louisiana DOTD can work on faster traffic incident management and better traffic signal coordination to lessen congestion-related emissions, but more carpooling could make an immediate impact if people would do it. “There will be a list of excuses from Miami to Anchorage as to why we can’t do that, but we can.”

He pointed out that, if people really don’t want to carpool, “maybe we can get them to plant a tree. You can absorb a lot of carbon dioxide through natural sequestration. Public properties can be re-forested. Government agencies and schools can add trees to parking lots. This could be mitigation for transportation.”

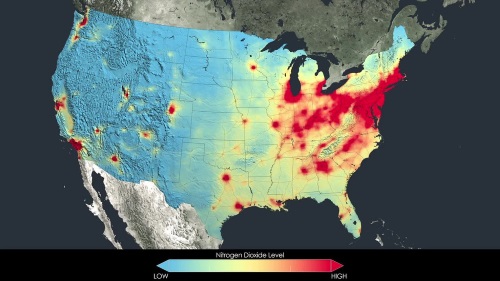

Because Louisiana has so many chemical plants and refineries, transportation emissions make up only 26 percent of GHG emissions – much less than other states, Kalivoda said. Industry is responsible for 49 percent, power production makes up 23 percent, and homes and other businesses account for the rest. The panel is expected to produce interim recommendations by the end of April, and a final report and recommendations by February 2022.